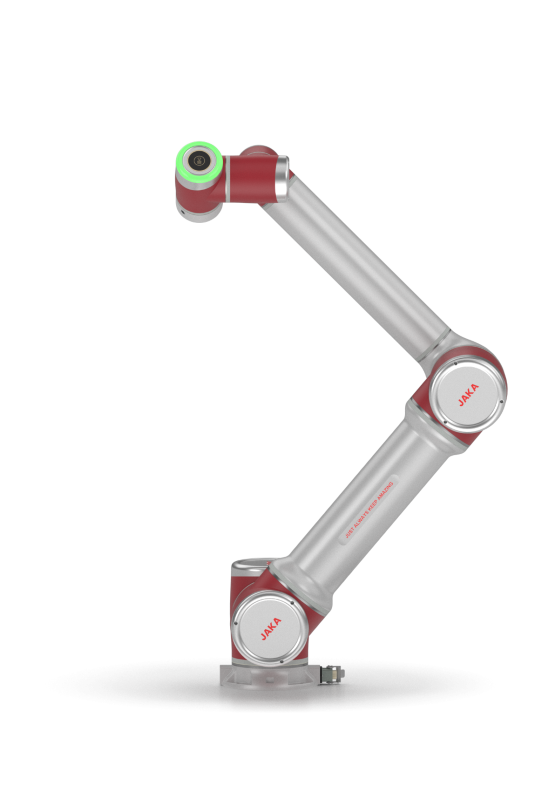

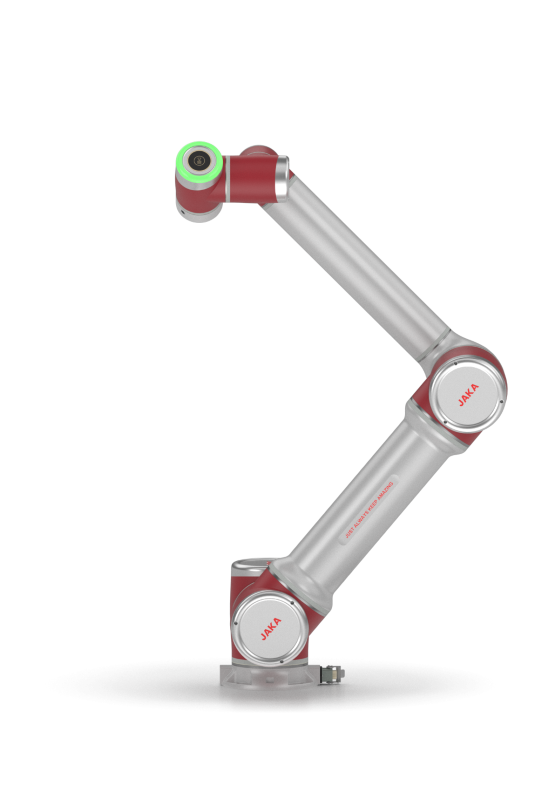

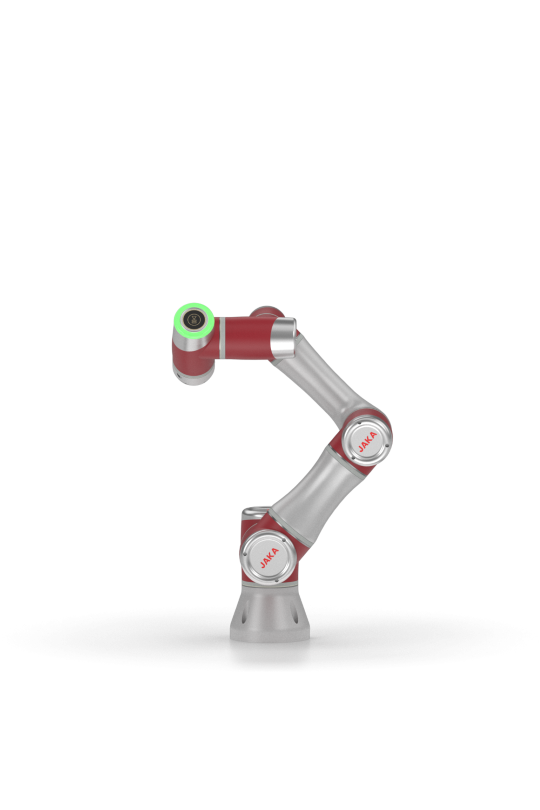

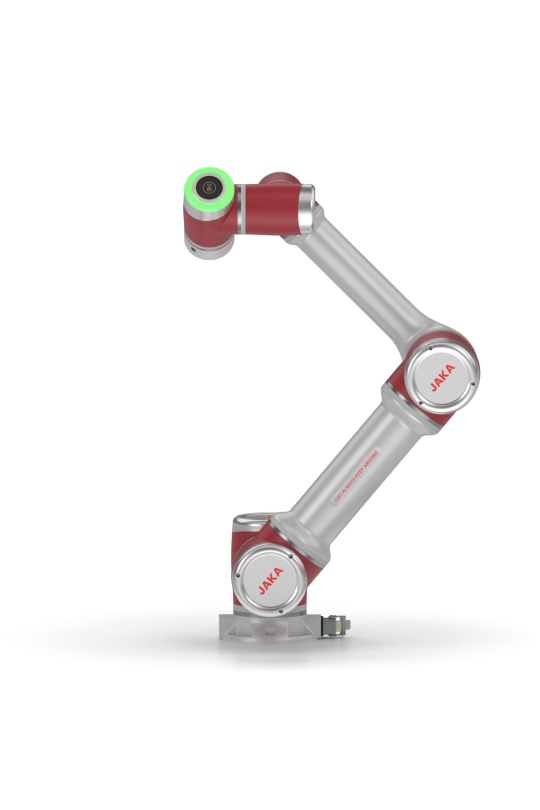

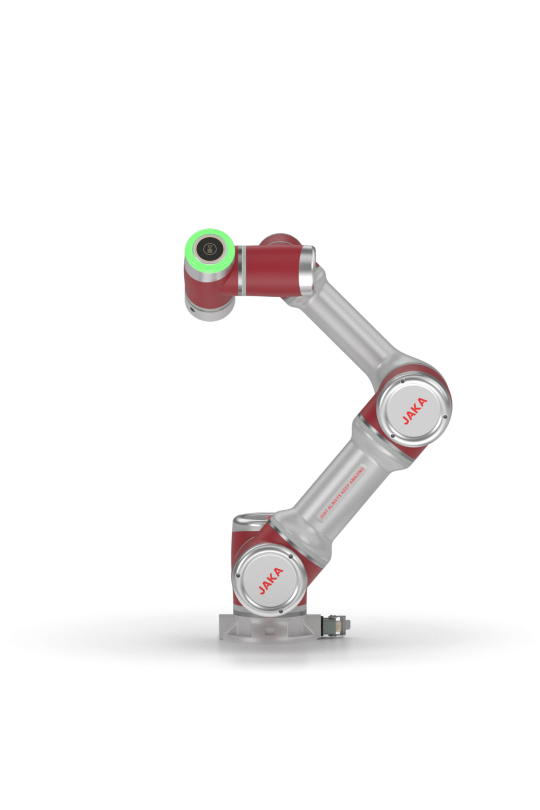

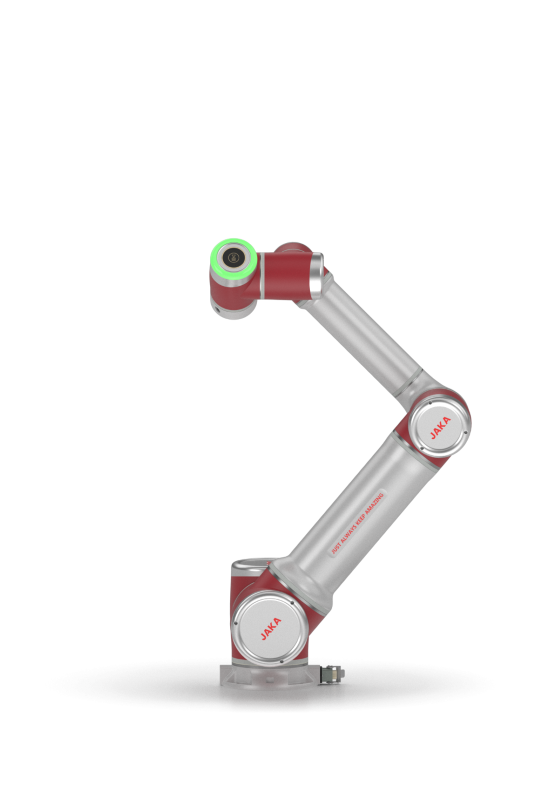

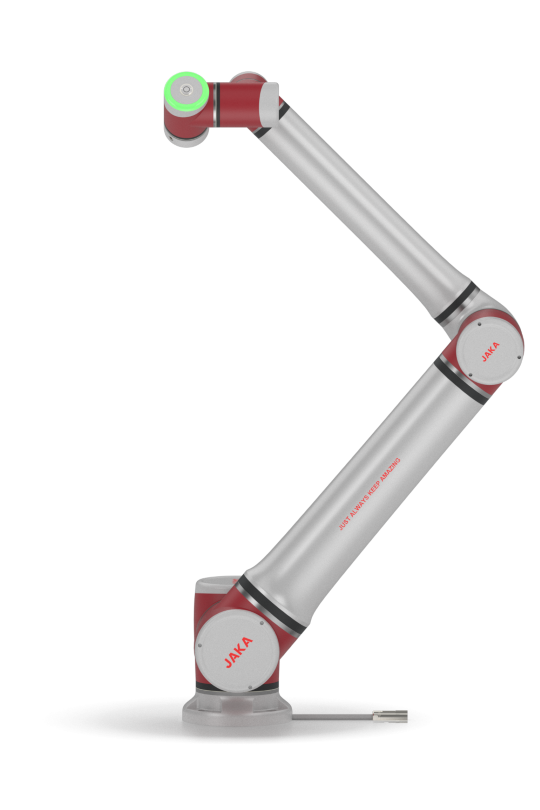

JAKA Zu12

Payload: 12 kg, Weight: 41 kg, Reach: 1327 mm

Human-robot-environment collaborative integration

Payload 12 kg, Self-weight 41 kg, Reach 1327 mm

Integrated joint design, easy to assemble and disassemble

Higher payload and longer arm span, competent for heavy manual labor tasks

Adhering to the concept of ""human-robot-environment collaborative integration"", high safety design eliminates the need for isolation fences

Contact UsHuman-robot-environment collaborative integration

Payload 12 kg, Self-weight 41 kg, Reach 1327 mm

Integrated joint design, easy to assemble and disassemble

Higher payload and longer arm span, competent for heavy manual labor tasks

Adhering to the concept of ""human-robot-environment collaborative integration"", high safety design eliminates the need for isolation fences

Product Features

suitable for heavy-duty tasks

06

suitable for heavy-duty tasks

Product Parameters

Weight (including cables)

41 kg (90.39 lb)

Repeatability

±0.03 mm (±0.00118 in)

Degree of freedom

Graphical programming, and freedrive programming

Programming

Mobile terminal (computer/pad/mobile phone)

Humidity

2 digital inputs/

2 digital outputs/

2 analog inputs

Footprint

188 mm (7.402 in)

l/0 ports

16 digital inputs, 16 digital outputs, 2 analog inputs or outputs

Communication mode

TCP/IP,Modbus TCP,Modbus RTU, Profinet, Ethemet/lP

Power supply

100-240VAC,50-60Hz

Size

410×307×235 (mm) (W×H×D)

Series Products

Application Scenario

Loading and Unloading

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Packing

Can spray complex curves with precision control to save paint .

High-precision repeatability ensures product quality, reducing operational costs and minimizing reworked parts and scrapped parts.

Replaces manual labor, reduces management costs, effectively improves production rate

Palletizing

Achieves automated palletizing, improves production efficiency, and enhances the working environment for operators.

A single robot can manage multiple production lines, significantly reducing costs

Compact structure, small footprint, high integration, and lightweight, effectively solving manual palletizing tasks on-site for customers.

Handling

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.